Automotive Wire Harness: Essential Vehicle Components

Automotive Wire Harness: Essential Vehicle Components

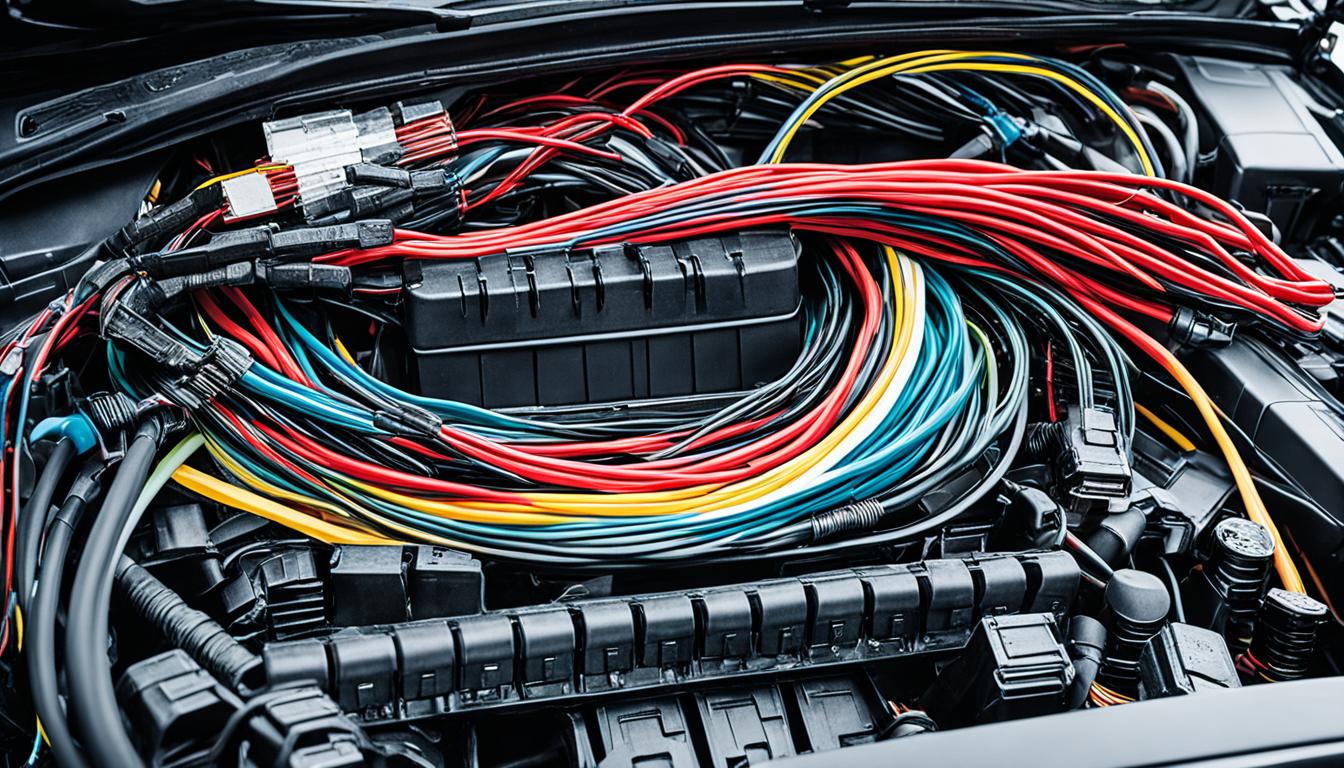

In the world of cars, the wire harness is key. It's like the main road for electrical signals and power. This article will cover what wire harnesses do, why they're important, and the different types for cars.

A wire harness is made of wires, cables, and connectors. It sends electrical signals and power around the car. It makes sure everything electrical works right, from the engine to the music system.

Key Takeaways

- Automotive wire harnesses are the essential backbone of a vehicle's electrical systems, transmitting signals and distributing power.

- Wire harnesses come in various types to meet the specific needs of different vehicle models and components.

- Understanding the definition, purpose, and components of wire harnesses is crucial for maintaining the safety, reliability, and cost-effectiveness of automotive electrical systems.

- The manufacturing process of wire harnesses is a complex and specialized field, requiring precision and attention to detail.

- Quality wire harnesses are essential for ensuring the smooth and safe operation of a vehicle's electrical systems.

What is an Automotive Wire Harness?

An automotive wire harness is key to a vehicle's electrical setup. It's a bundle of wires, cables, and connectors that carry electrical signals and power. The main job of a wire harness is to keep these electrical connections safe and efficient. This ensures all the car's systems work well together.

Definition and Purpose

A wire harness is made up of wires, cables, and parts that are all put together. They help distribute electrical power and signals in a vehicle. This harness connects different parts of the car, letting them talk to each other and work together smoothly. It makes the car's electrical system safer, more efficient, and reliable.

Types of Wire Harnesses

There are different kinds of automotive wire harnesses, each for a specific job in the car. Here are a few:

- Engine harness: Connects the engine's electrical parts, like the alternator, sensors, and ignition system.

- Body harness: Handles electrical connections for inside and outside the car, like lights, entertainment systems, and safety features.

- Specialized harnesses: These are for certain systems, like lights, air conditioning, or car communication systems.

These harnesses work together to make a complete electrical network in the car. This network lets all the car's systems and parts work together smoothly.

| Wire Harness Type | Purpose |

|---|---|

| Engine Harness | Connects engine electrical components like alternator, sensors, and ignition system |

| Body Harness | Manages electrical connections for interior and exterior features like lighting, infotainment, and safety systems |

| Specialized Harnesses | Dedicated harnesses for specific systems like lighting, air conditioning, or telematics |

"The wire harness is the backbone of a vehicle's electrical system, providing a organized and protected pathway for the flow of power and signals throughout the car."

Wire Harness, Automotive: The Backbone of Vehicle Electrical Systems

The automotive wire harness is key to the complex network of vehicle electrical systems. It connects wires, cables, and connectors, making sure all electrical parts work together. This includes the engine, lights, entertainment, and safety features.

Without a working wire harness, a car's electrical system would be a mess. It would lead to problems with performance, safety, and reliability. The role of wire harnesses is vital for a smooth drive, making sure everything electrical works well together.

The importance of wire harnesses goes beyond just working well. They also help keep a car's structure strong and balanced. They are carefully placed to avoid damage and ensure everything fits right.

"The automotive wire harness is the backbone of a vehicle's electrical system, connecting all the essential components and ensuring seamless operation."

As cars get more advanced and go electric, the role of wire harnesses will grow even more important. It's crucial that they are made to the highest quality. This ensures they can handle the power needs of modern vehicles.

Components of a Wire Harness

The automotive wire harness is made up of many parts that work together. They send electrical signals and power around a vehicle. At the center are the wires and cables that carry the electricity. Also, the connectors and terminals make sure the wiring connects well to the car's parts.

Wires and Cables

Wires and cables in a wire harness vary in size, material, and insulation. They send electrical signals and power to different parts of the car or truck. Picking the right wires and cables is key for the harness's performance and life.

Connectors and Terminals

Connectors and terminals are crucial in the wire harness. They connect the wiring to the car's electrical parts. They come in many designs, materials, and sizes for different car needs. The quality of these parts is important for keeping the wire harness working well and avoiding electrical problems.

| Component | Purpose | Example |

|---|---|---|

| Wires and Cables | Transmit electrical signals and power | Copper wire with PVC insulation |

| Connectors and Terminals | Provide secure and reliable connections | Stamped metal terminals with plastic housings |

Choosing and putting together these wire harness components is key. This includes the wires and cables and the connectors and terminals. It makes sure the car's electrical system works well, safely, and reliably.

Manufacturing Process of Wire Harnesses

The making of automotive wire harnesses is a detailed process. It ensures the quality and reliability of these key parts. Each step, from cutting wires to testing, is done with great care in a controlled space.

The wire harness manufacturing starts with cutting wires to the right lengths. Then, connectors and terminals are added. This step is vital for secure connections and keeping the electrical system safe. Technicians bundle the wires carefully to make sure they work well and don't get damaged.

Quality checks are key in making wire harnesses. They go through tests for electrical, mechanical, and environmental strength. This makes sure the automotive wire harness assembly is safe and works as it should. This focus on quality is crucial for a vehicle's electrical systems to work right.

Special tools and advanced methods are vital for making wire harnesses well. Automated machines and advanced tools help make high-quality products efficiently and affordably.

By using the best practices and top facilities, wire harness makers can make sure their products support modern vehicles' electrical systems well. This helps with the safety, performance, and life of the automotive industry.

The Importance of Quality Wire Harnesses

In the automotive world, quality wire harnesses are key. They ensure safety, reliability, and save money in cars. These harnesses are crucial for the car's electrical systems, making everything work smoothly.

Safety and Reliability

Strong and dependable wire harnesses keep drivers and passengers safe. They prevent electrical problems and fires, which are dangerous. By keeping safety systems like airbags and brakes working right, these harnesses make cars safer and more reliable.

Cost-Effectiveness

Quality wire harnesses also help save money. They make cars more energy-efficient and perform better, cutting down on repair costs. This means they offer a good value for both car makers and buyers.

FAQ

What is an automotive wire harness?

An automotive wire harness is key to a vehicle's electrical system. It's a bundle of wires, cables, and connectors. It acts like the vehicle's central nervous system, sending electrical signals and power around.

What are the main types of wire harnesses in vehicles?

Vehicles have different wire harnesses. There are engine harnesses, body harnesses, and special harnesses for things like lights, entertainment, and safety systems.

What is the role of a wire harness in a vehicle's electrical system?

The wire harness is vital for a vehicle's electrical system. It connects and communicates between different parts, like the engine and lights. This ensures the car works well, safely, and reliably.

What are the main components of a wire harness?

A wire harness has wires, cables, connectors, and terminals. These parts are chosen and made for quality. This ensures the harness works well and lasts long.

How are automotive wire harnesses manufactured?

Making automotive wire harnesses is complex. It includes cutting wires, connecting them, bundling, and testing. This is done in a controlled setting for quality. Special tools, skilled workers, and strict quality checks are needed.

Why is the quality of a wire harness important?

Quality wire harnesses are key for vehicle safety, reliability, and saving money. They make sure important electrical systems work right, lowering the chance of problems or fires. They also make the car run better, use less energy, and cost less to maintain over time.