Wire Harness & Electric Bus: Powering Green Transport

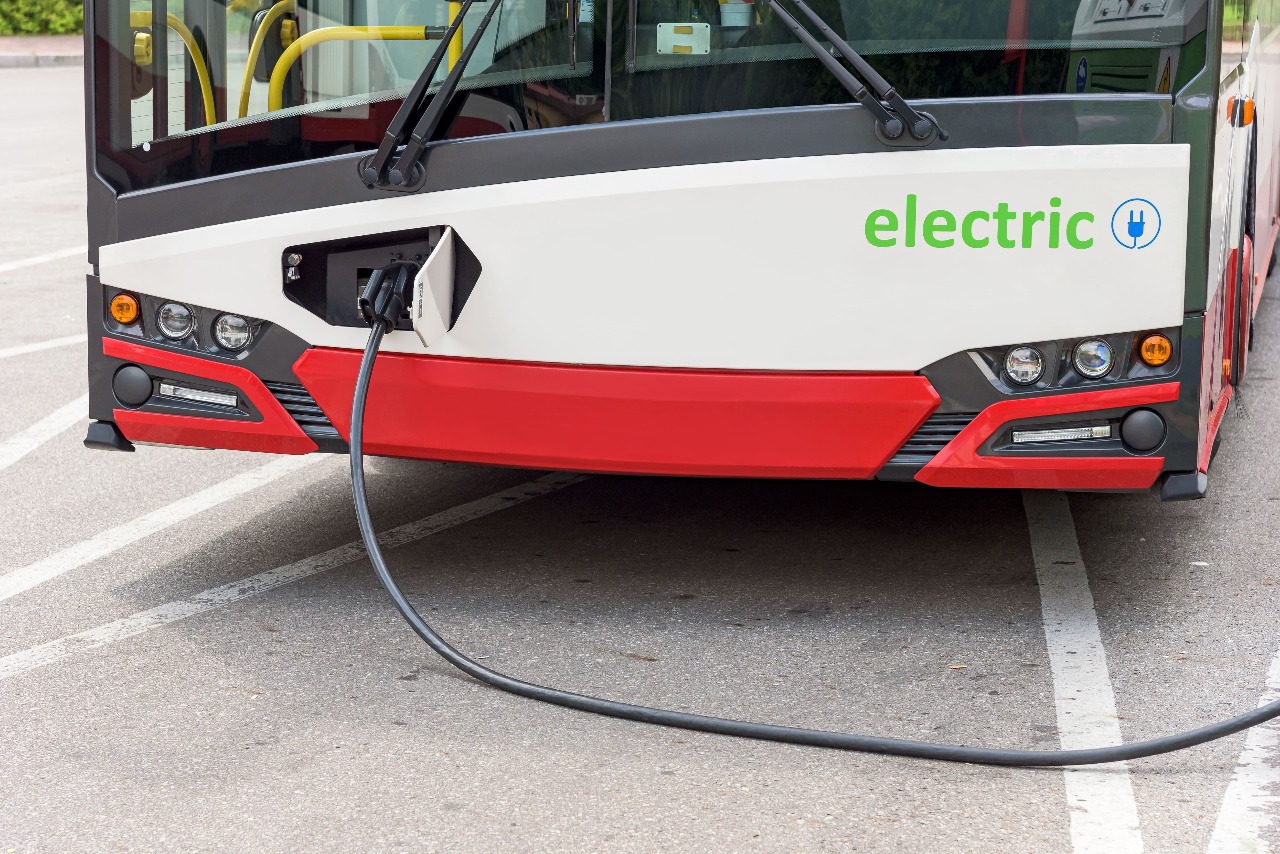

The world is moving towards a sustainable future, and electric buses are key to this change. At the center of this shift is the wire harness. It's a vital part of electric bus technology. This article will explore how wire harnesses work, their design, and their role in making electric buses more efficient and eco-friendly.

Wire harnesses are complex systems of cables and connectors that power an electric bus's electronics. They're essential for sending electrical signals and distributing power. They also ensure the bus runs efficiently, reliably, and safely. By looking into how these harnesses are designed and managed, we see the amazing engineering behind electric buses.

Key Takeaways

- Wire harnesses are the backbone of electric bus technology, enabling the seamless integration of advanced components.

- Effective thermal management strategies are crucial for ensuring the longevity and performance of electric bus wire harnesses.

- The environmental impact of electric buses powered by wire harnesses is significant, contributing to reduced carbon footprints and greener transportation.

- Innovations in materials and design are enhancing the reliability and durability of wire harnesses, further supporting the growth of the electric bus industry.

- Addressing the challenges in wire harness design is key to unlocking the full potential of electric bus technology and driving towards a greener future.

Unveiling the Backbone of Electric Bus Technology

The electric bus industry is leading the way in sustainable transportation. At the core, the electric bus wiring harness is key. It powers the whole system.

- The Intricate Web: Understanding Wiring Harness Architecture

The wiring harness design in electric buses is amazing. It has a complex network of cables, connectors, and parts. This network is like the vehicle's nervous system, sending data and power to different parts.

Understanding this complex wiring needs deep knowledge of its design. Planning, routing, and attention to detail are key. They make sure all parts work together smoothly in the electric bus.

- Keeping It Cool: Thermal Management in Electric Bus Wire Harnesses

Managing heat from high-voltage parts in electric bus wiring harnesses is a big challenge. Good thermal management is vital for the system's performance and life.

Using heat sinks and airflow management helps cool the wiring harness. This keeps it safe and reliable, making the electric bus better.

|

Key Considerations in Electric Bus Wiring Harness Design |

Thermal Management Strategies |

|

|

By understanding electric bus wiring harnesses and how to manage heat, engineers are making electric buses better. This leads to a greener and sustainable future for transport.

Wire Harness, Electric Bus: A Symbiotic Relationship

The link between wire harnesses and electric buses is key to making transportation more sustainable. These two work together, creating a partnership that makes electric buses run well and reliably.

At the center of an electric bus is a complex wiring system. This system sends power, data, and control signals all over the vehicle. Wire harnesses are made with electric buses in mind. They are essential for the electric bus system design and the electric bus powertrain components.

The detailed wire harness and electric bus integration lets different parts of the bus work together. This includes the battery, motor controllers, and safety systems. This teamwork is key for the bus to perform well, save energy, and be reliable.

- Efficient power distribution: Wire harnesses send power from the battery to the electric motor. This ensures energy is used well and losses are cut down.

- Data communication: These harnesses help share important data between the bus's parts. This lets for real-time monitoring and control.

- Thermal management: The design of the wire harness includes ways to manage heat from the electric powertrain. This keeps the bus running at the best temperature.

Understanding how wire harnesses and electric buses work together helps engineers create new solutions for sustainable transport. As more people want electric buses, this partnership will become even more important. It will help make our future greener and more efficient.

Embracing Sustainability: The Environmental Impact

The world is facing a big challenge with climate change. The way we travel is a key part of this problem. Luckily, electric buses are becoming a big help. They use advanced technology to cut down on pollution and help us move towards a cleaner future.

Reducing Carbon Footprints with Electric Bus Systems

Electric buses are much better for the environment than diesel buses. They don't produce any direct emissions, which means no harmful pollutants like carbon dioxide, nitrogen oxides, and particulate matter. This big drop in emissions is a key step towards making our transport more sustainable.

- Electric buses are a clean and efficient choice, making cities' air cleaner.

- They use regenerative braking to save energy and cut down on emissions even more.

- Improvements in wire harnesses, keeping things cool, and new materials have made electric buses better and more reliable. This makes them a great option for eco-friendly transport.

By choosing electric buses, we're all working towards a future where our transport is both efficient and kind to the planet. The big cuts in emissions from electric buses show how innovation and commitment can lead to a better future.

Crafting Reliable and Durable Wire Harnesses

In the electric bus world, the wire harness is key. It needs to be very reliable and last a long time. Companies are always looking for new materials and designs to make these systems better.

Material Innovations: Enhancing Longevity and Performance

Choosing the right materials is crucial for reliable wire harnesses. New thermoplastics and elastomers are being developed. They resist heat, chemicals, and stress well. These materials make wire harnesses last longer and work better.

Manufacturers are also trying new ways to make wire harnesses more reliable and durable. Techniques like overmolding and multi-shot injection molding add extra strength and seals. This makes wire harnesses ready for the tough life of electric buses.

|

Material Innovation |

Key Benefit |

|

High-performance thermoplastics |

Improved heat resistance and chemical resilience |

|

Advanced elastomeric compounds |

Enhanced mechanical durability and flexibility |

|

Integrated reinforcing elements |

Increased structural integrity and impact resistance |

By using material innovations and new ways to make them, wire harness experts help electric buses run well for a long time. This makes green transportation better and more efficient.

Challenges and Solutions in Wire Harness Design

Designing wire harnesses for electric buses is a complex task. These systems must power the bus and handle daily use without issues. With more people wanting eco-friendly transport, designers face new challenges. They need to think creatively and use the latest tech to solve these problems.

One big challenge is dealing with the high voltage needed for electric buses. The wiring must safely handle a lot of power while keeping everything safe and cool. It's all about finding the right balance with materials and tech.

- Thermal management: Ensuring the wire harness can dissipate heat generated by high-voltage components without compromising performance or safety.

- Electromagnetic compatibility: Mitigating the impact of electromagnetic interference (EMI) on sensitive electronic systems within the bus.

- Weight optimization: Minimizing the overall weight of the wire harness to enhance the bus's energy efficiency and range.

New solutions are being developed to tackle these issues. For example, using lightweight, heat-resistant materials is making wire harnesses better. Also, new design methods and algorithms are making manufacturing more efficient and improving performance.

Wire harness designers must keep up with the latest in electric bus tech. By using new solutions, they help make electric buses better. This is key to a greener future.

Conclusion: Driving Towards a Greener Future

Looking back at the journey of wire harnesses in electric bus technology, we see their key role. These unsung heroes are crucial for sustainable transport. They help make electric buses more efficient and green.

Wire harnesses and electric buses work together to cut down on pollution and improve air quality in cities. By joining this green movement, we help our planet and create a better transport system for the future.

The wire harness industry is always finding new ways to improve with materials and reliability. As we move towards a greener future, these heroes will be key. They will help us switch to sustainable transport, making life better for everyone.

FAQ

What is the role of wire harnesses in electric bus technology?

Wire harnesses are key to electric bus technology. They make sure the bus runs well and reliably. They connect different parts of the bus, letting power and data flow smoothly.

How do wire harnesses contribute to the thermal management of electric buses?

Wire harnesses need to manage heat well to last long and work right. New designs and materials help spread out heat. This stops overheating and keeps the bus running perfectly.

What environmental benefits do electric buses powered by wire harnesses offer?

Electric buses with wire harnesses are great for the planet. They cut down on carbon emissions and help make the future greener. By not using fossil fuels, they make moving around cleaner and support a greener future.

How do material innovations enhance the reliability and durability of wire harnesses in electric buses?

New materials and designs are key to making wire harnesses better. They help harnesses last longer in tough bus conditions. This means they work well for a long time, making buses more reliable.

What are the main challenges in wire harness design for electric buses, and how are they being addressed?

Designing wire harnesses for electric buses is tough. Engineers must balance weight, manage heat, and make strong connections. Researchers are working on new solutions to tackle these issues. This will make wire harnesses better for electric buses.